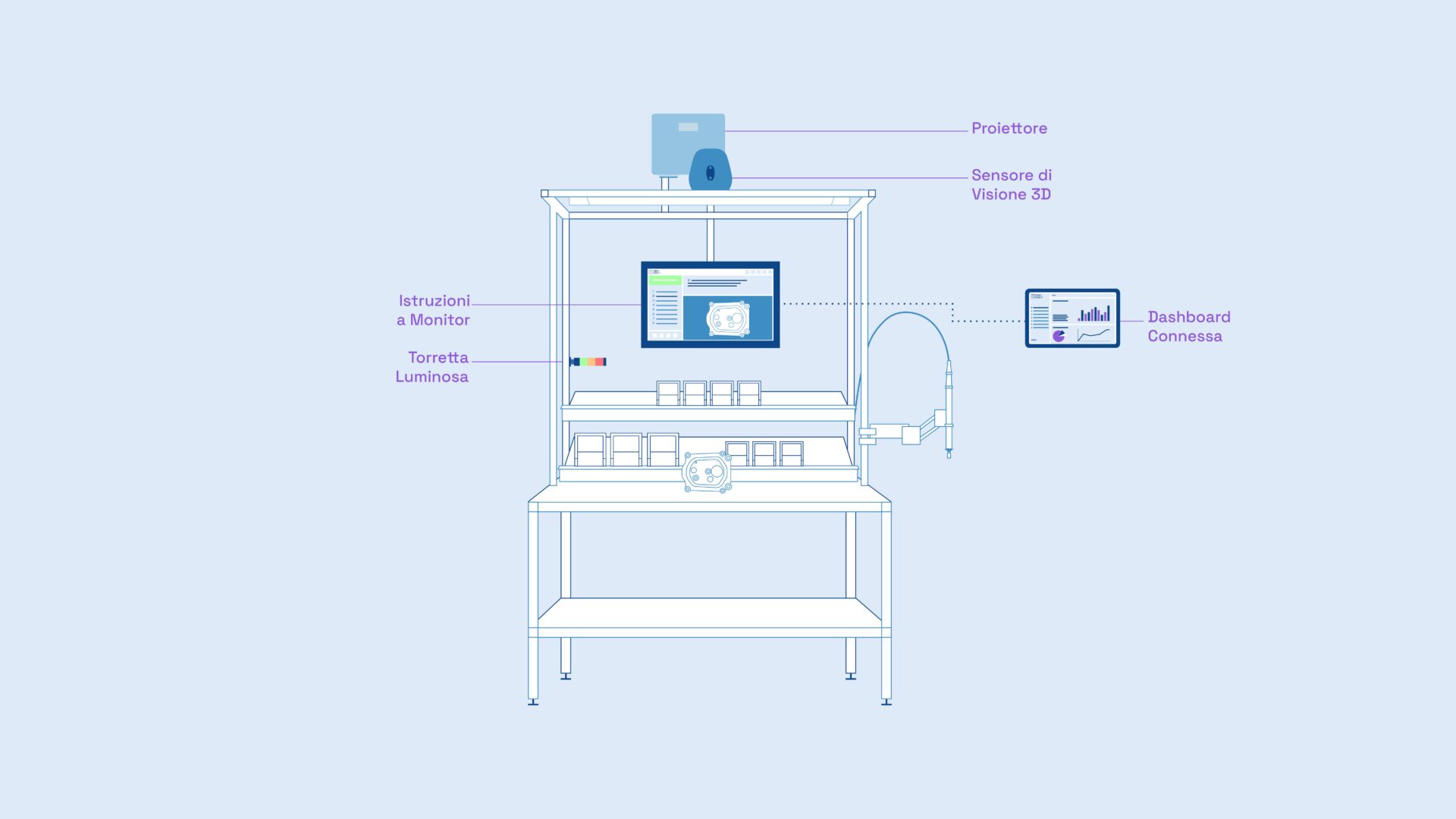

SRv3 from Smart Robots is an innovative digital colleague that collaborates with human operators to avoid errors and to improve quality and productivity while respecting privacy.

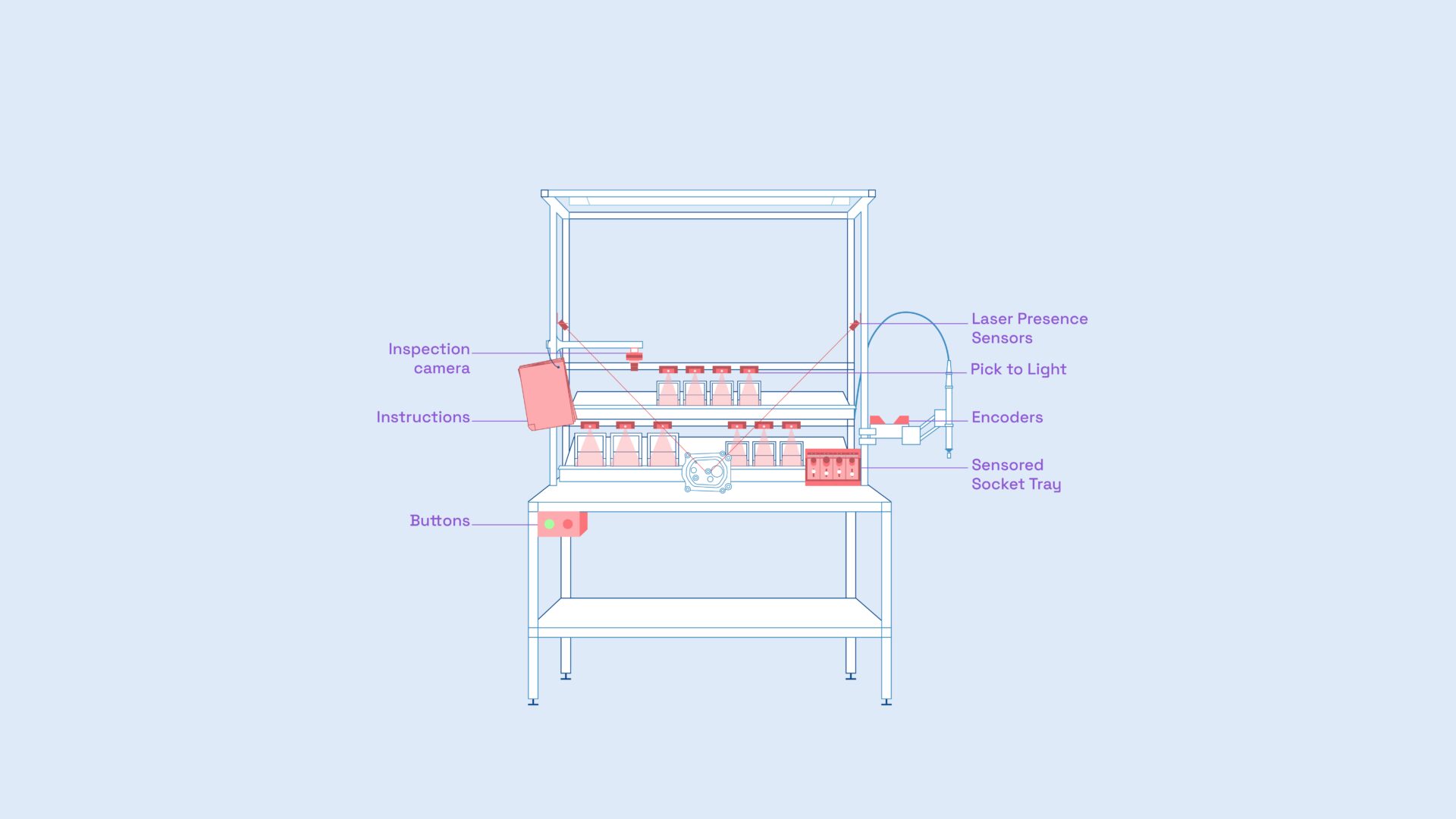

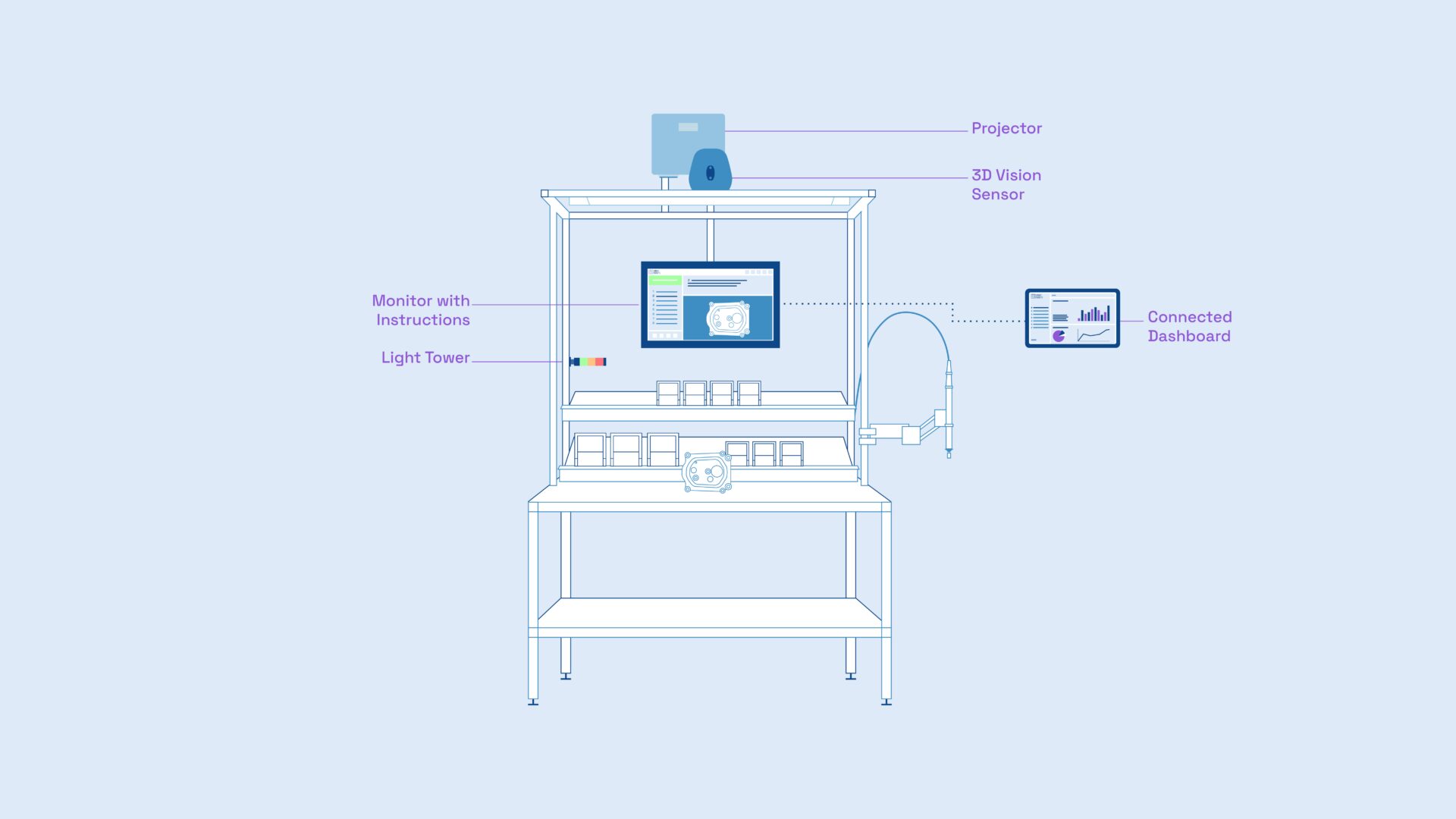

MODULAR AND PLUG AND PLAY FUNCTIONALITIES

IN A DIGITAL AND INTEGRATED PLATFORM

Digital excellence

Traceability, real-time dashboards and offline reporting for detailed and high-level analysis for MTM, line balancing, certification and processes continuous improvement

DISCOVER DETAILS OF FUNCTIONALITIES

How to check whether the operators perform the correct actions in the correct sequence?

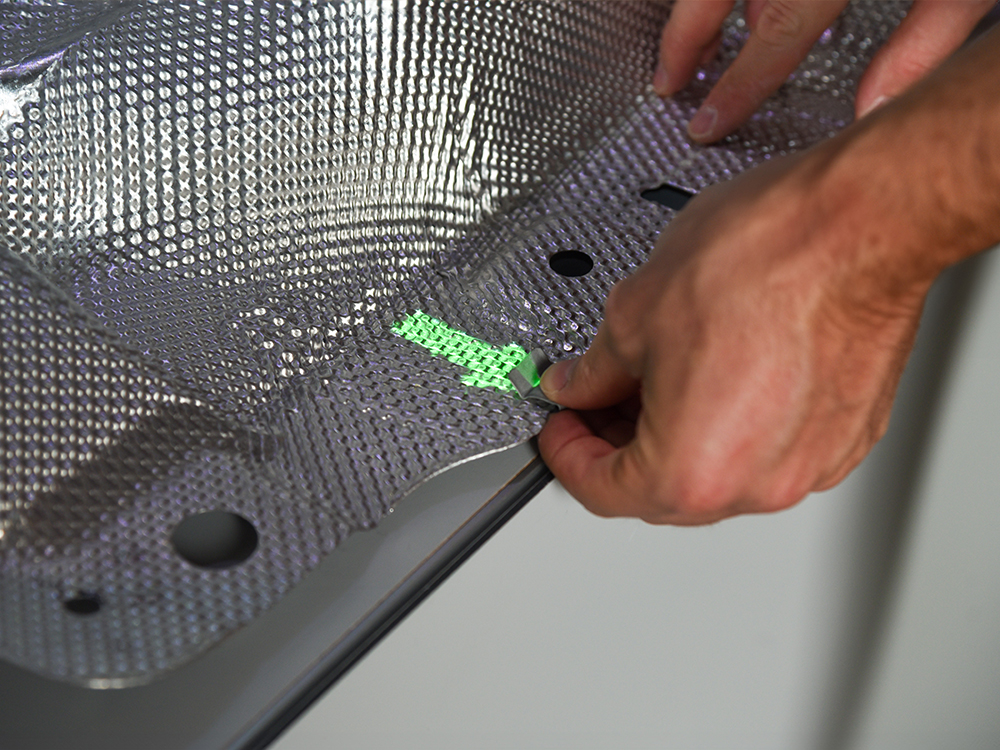

RECOGNITION OF OPERATOR’S HANDS

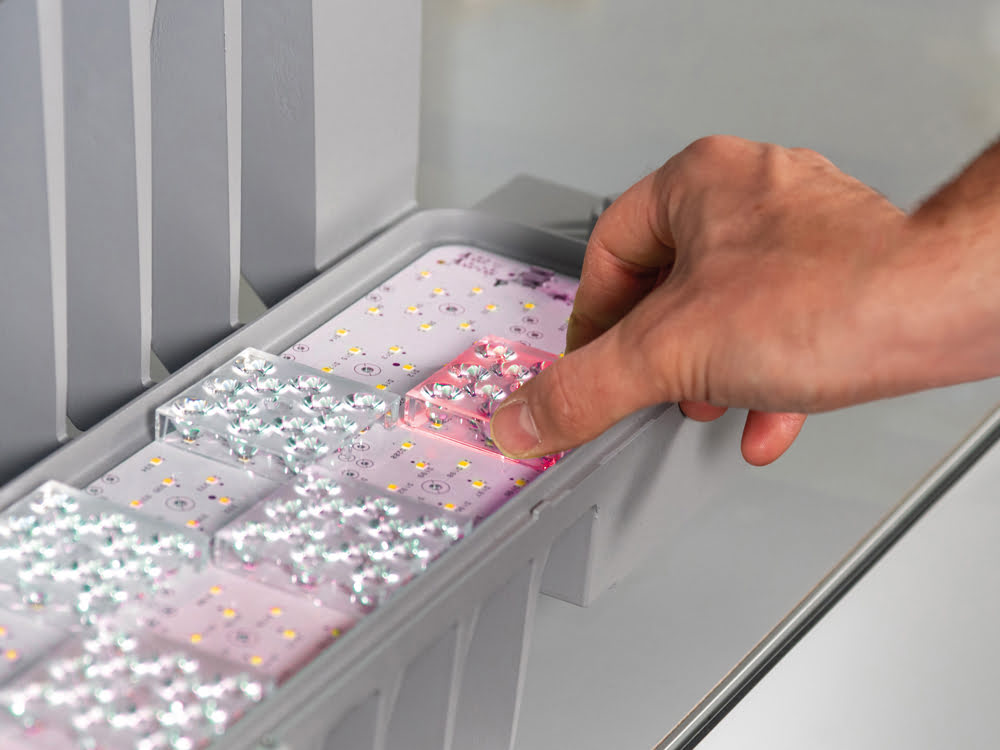

Hand tracking enables the certification of actions such as gripping from the box, even on several overlapping levels thanks to 3D vision, or the closing of knobs, the insertion of components and operations performed with the fingers.

POKA-YOKE TIGHTENING CONTROL

The product also checks whether the screwdriver (or other tools such as pliers, riveters, etc.) is positioned in the correct volume and in the correct sequence, only enabling it at that point and also checking that the correct torque or angle is reached.

VIRTUAL BUTTONS

Hand recognition can also be used to enable virtual buttons to give quick, intuitive and digital feedback.

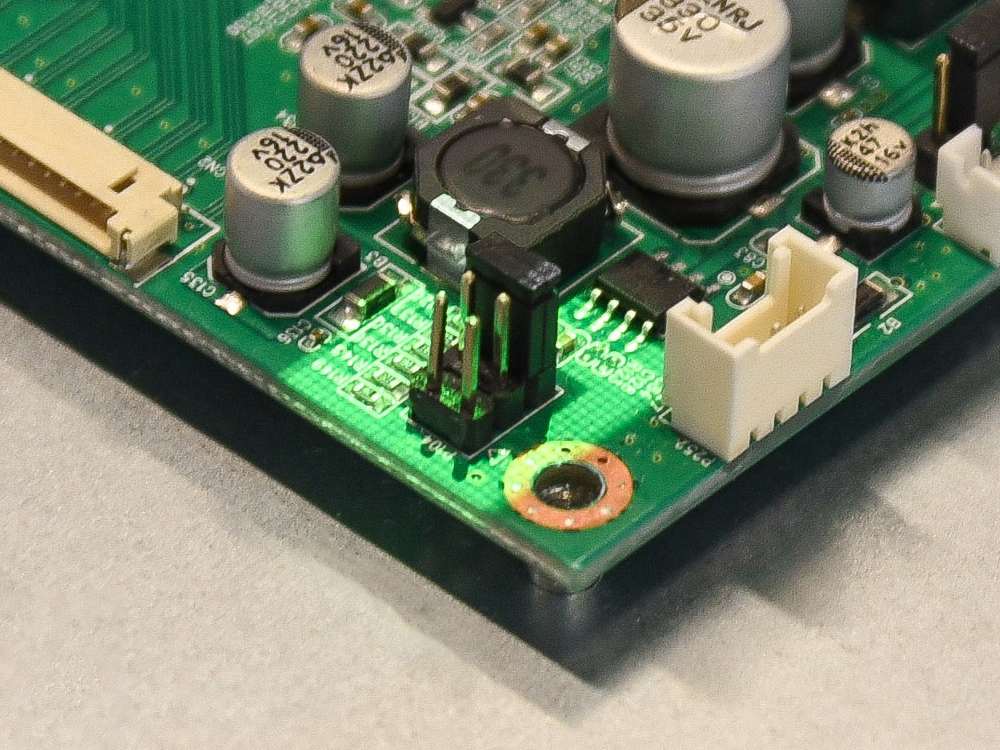

Certifying the presence of screws, plugs, clips, gaskets, heaters, lenses, instruction manuals and general components in the assembly or packaging is a common necessity.

RECOGNITION OF COLOUR, SHAPE AND HEIGHT IN 3D

The product recognises and verifies the presence and characteristics of objects and components based on colour, shape and height at each point of the component.

It even works with transparent objects because it can measure their height!

THE MOST ACCURATE ON THE MARKET WITH A SINGLE SENSOR

With a single sensor, the product can recognize objects, even transparent ones, up to 5mm in size by placing the sensor 1.5m from the object.

USE OF ADDITIONAL CAMERA FOR DETAILS OF MINIMUM SIZE

Objects as small as 5mm down to 0.5mm can be recognized by positioning the sensor closer and/or using an additional detail camera.

For example, the system is widely used to detect electronic components such as the black spacer in the picture.

When job rotation is frequent, there is high turnover, or processes are rather complex and variable, it becomes crucial to guide operators with digital, intuitive, interactive and easily updated instructions.

DIGITAL INSTRUCTIONS AND IMMEDIATE FEEDBACK

The basic module provides on-screen guidance, with instructions in the form of text, images and shapes overlaying the sensor view, which update with each step taken by the operator.

Feedback is also returned via the light tower to alert the operator immediately in the event of an error.

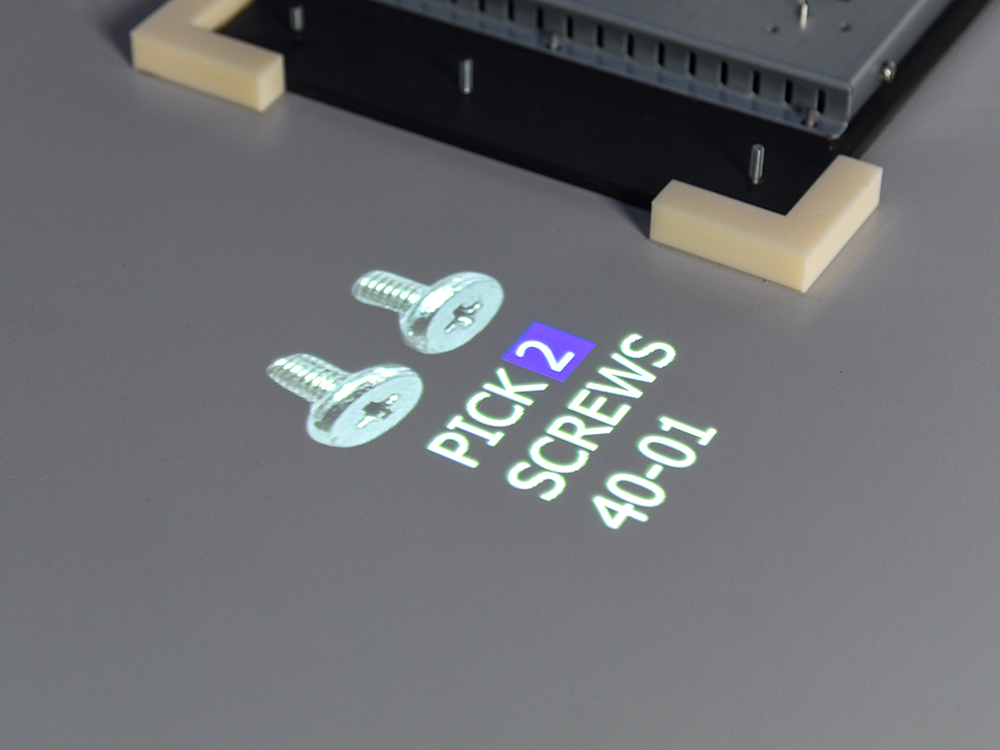

INTUITIVE AND CLEAR AUGMENTED REALITY

It is possible to add the augmented reality module to project coloured instructions onto the work area in the form of images, videos, text and shapes (such as arrows or circles).

Projections can be made directly onto the object to be assembled to guide actions such as screwing, clip insertion or similar.

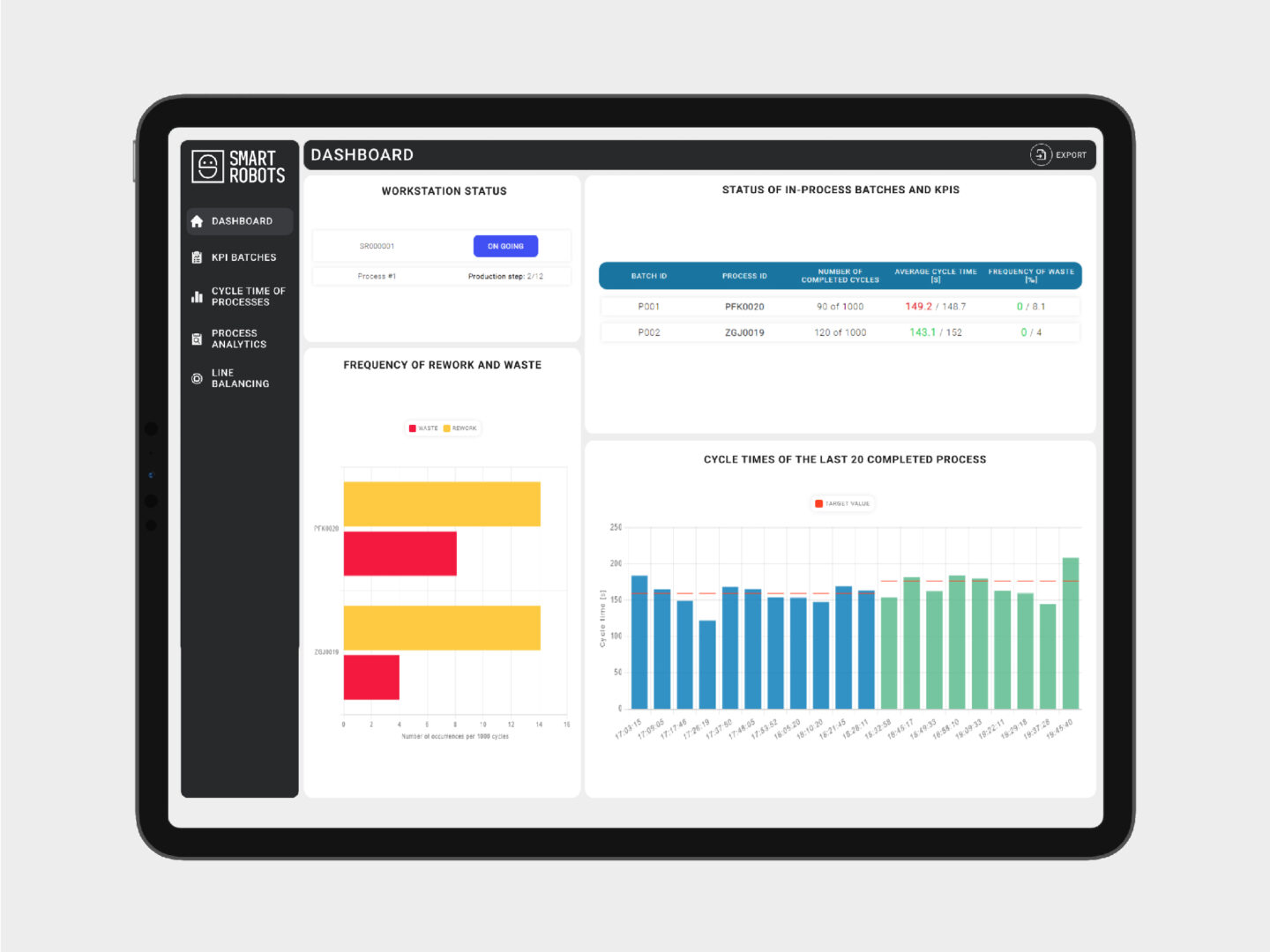

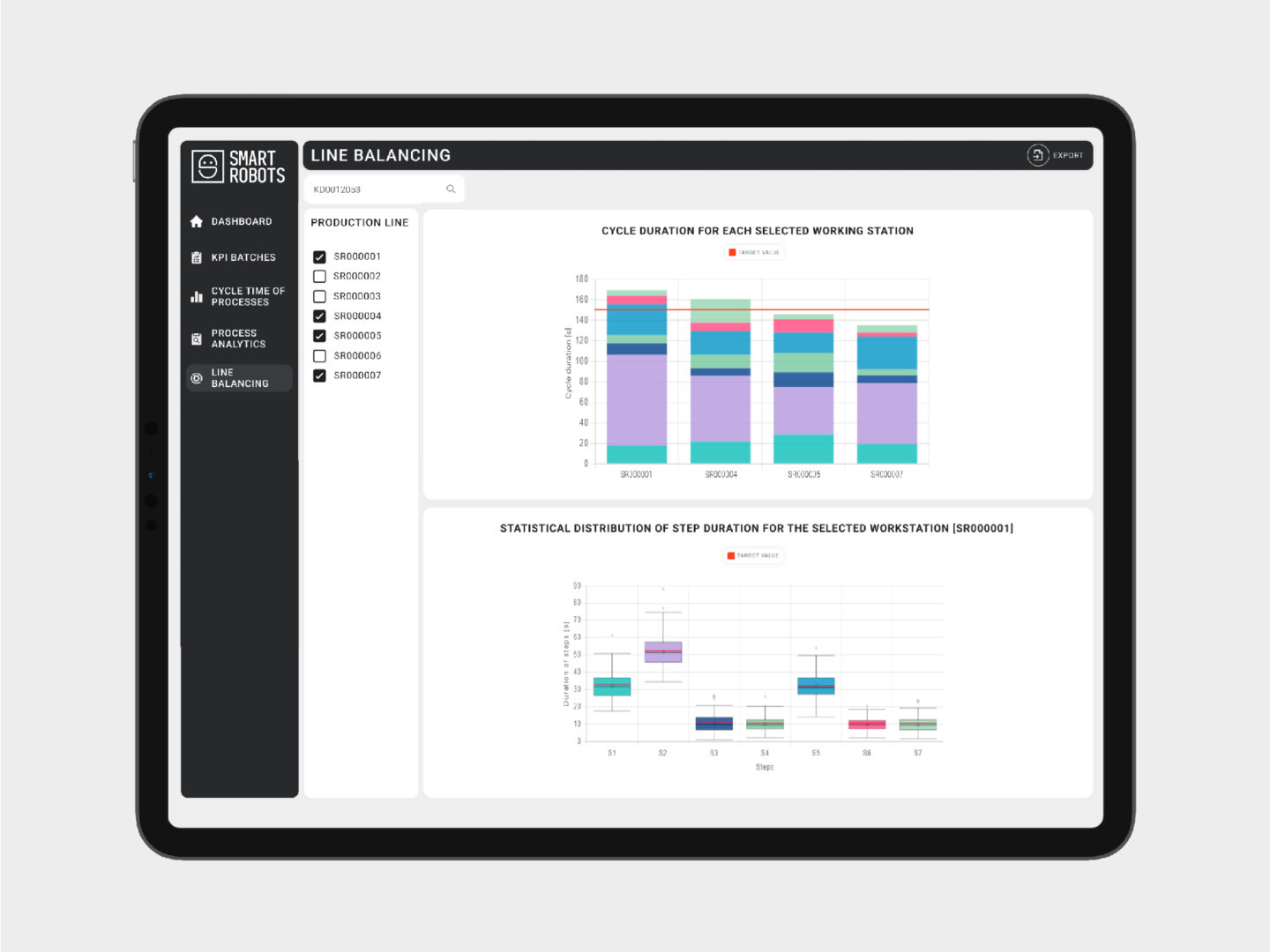

The Analytics module enables off-line reporting and on-line dashboards on workstations that become fully digitiZed.

UNIQUE AND EASILY ACCESSIBLE DATA

The product makes it possible to obtain data, analytics, statistics and insights on the manual workstation, otherwise not possible to obtain, of unique value for MTM analysis and line balancing. Data is provided via a graphical dashboard and via reports (SQL or CSV).

At a specific moment in the activity, e.g. just before the box is closed during packaging, the product can take a picture and send it to the company database, linked to the product serial number. The result is certification of production and the possibility of responding with concrete evidence to any customer complaints.

DATA-DRIVEN LINE BALANCING

The analytics module provides averages and variances of the timings of every single action of every single process of the different line stations in the defined time intervals.

The MTM manager can then balance the activities on the different line stations on the basis of objective, continuous and homogeneous data.

STANDARD AND CUSTOMIZED INTERFACES WITH MANUFACTURING MANAGEMENT SOFTWARE

Interconnection with the factory’s digital infrastructure is easy, standard and immediate, both with the production management software (MES or MOM) and with the workplace tools.

Interfacing with MES and MOM and production supervision software, in order to receive commands and return results and monitoring data, are realised with the most common and widespread protocols, such as MQTT, OPC-UA, Open Protocol, TPC/IP, REST-API, SQL. Customised solutions are also offered.

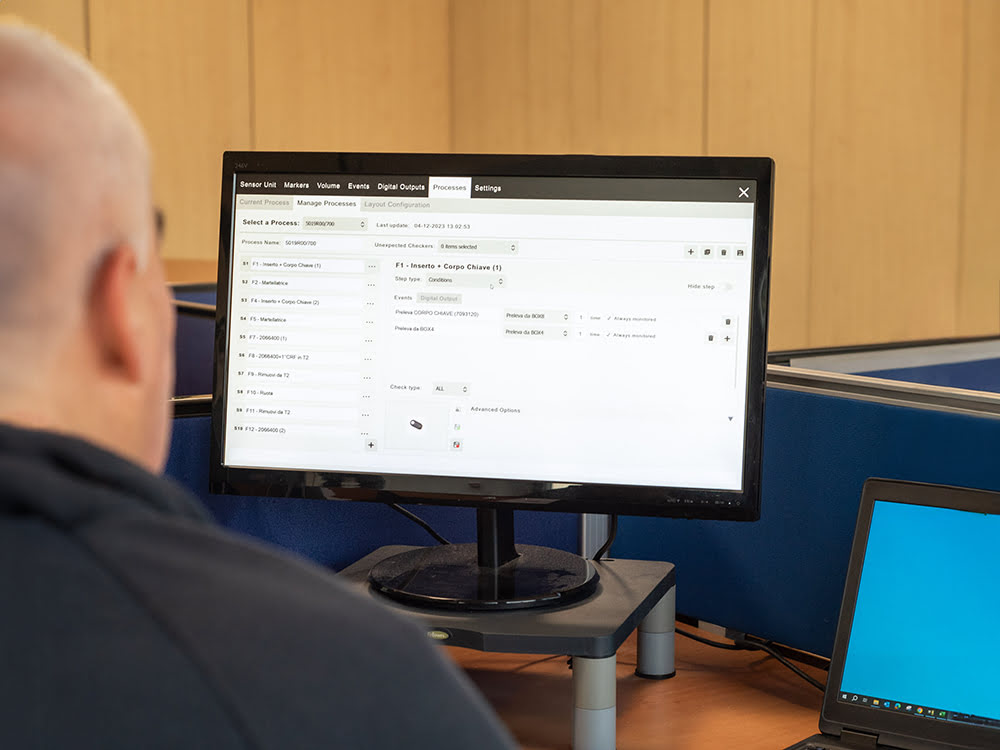

The management software can send the code of the current process or product to SRv3, and the operator is immediately guided through the correct procedure. The process can also be changed by reading a barcode or via a graphical interface.

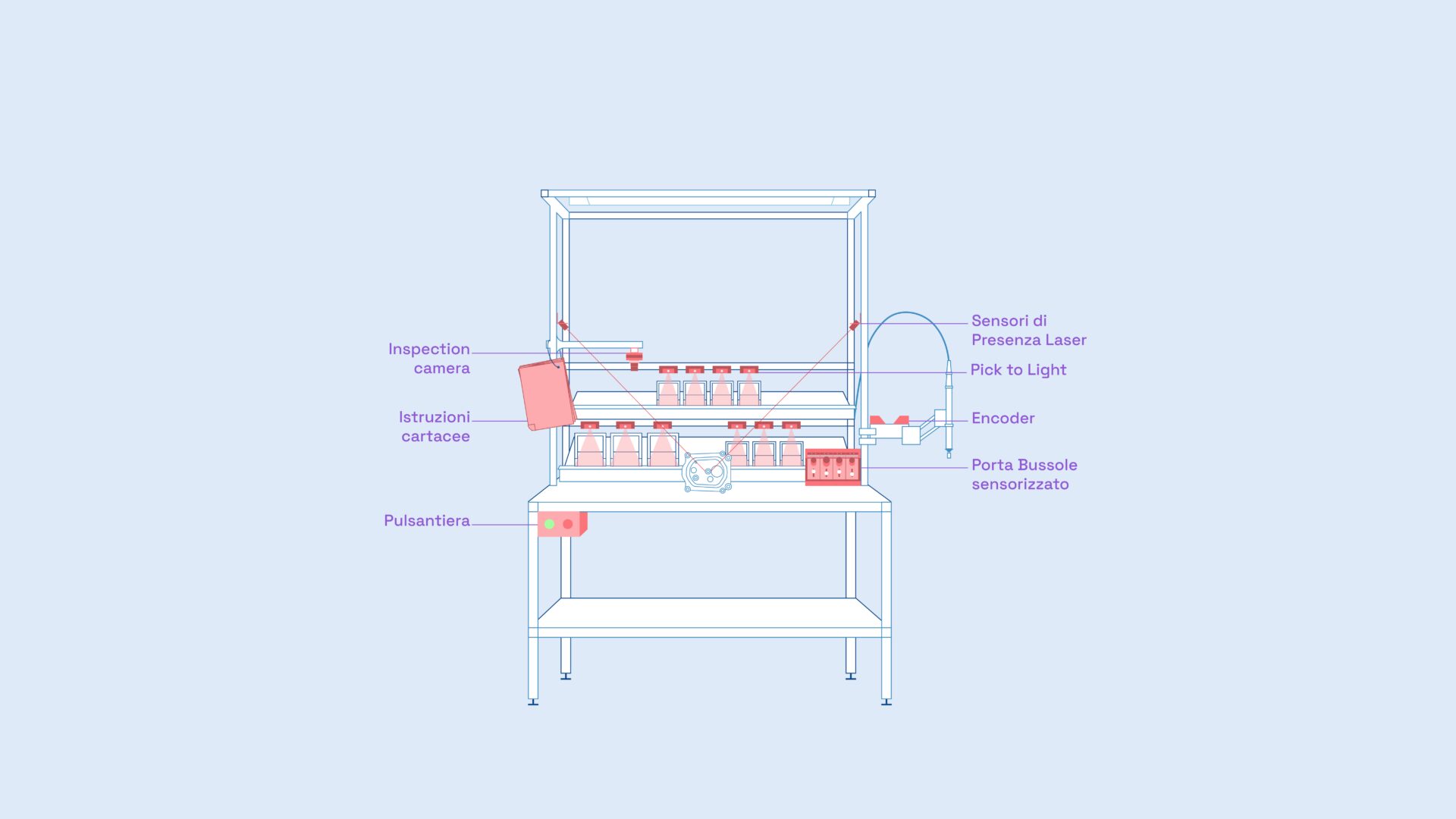

CONNECTIVITY WITH WORKBENCH EQUIPMENT

Connections and Digital I/O are available for station equipment, such as testing machines, screwdrivers, sensors, LEDs and drives. The SRv3 product can therefore act as a station manager, replacing PLCs and/or Panel PCs, and as a data collector.

STAND-ALONE PRODUCTION SUPERVISOR FOR SME AND MES SOLUTIONS

If the factory does not have a production supervisor, the Smart Robots solution can take its place by being able to monitor and manage production orders, alert the operator when the order target is reached, and create reports on the orders. Smart Robots can also provide a bundled solution with MES supplier partners.

REMOTE CONNECTIVITY TO THE WORKSTATION

The system also allows remote connection to the workstation for an instant and efficient supervision and configuration experience.

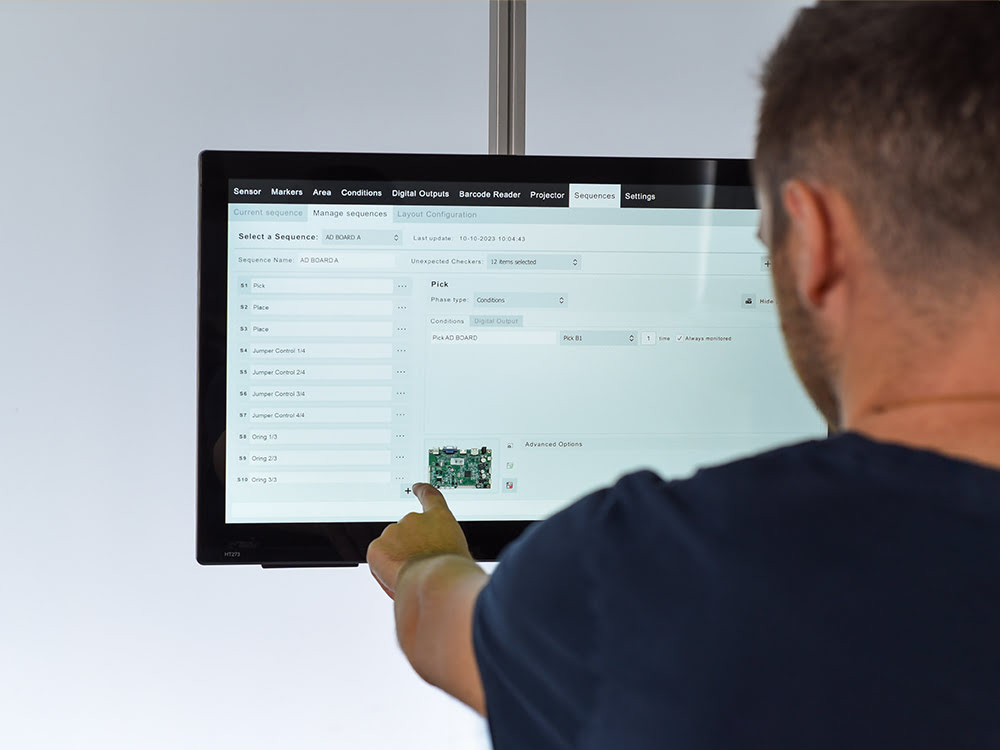

One of the most important features of Smart Robots’ SRv3 solution is the ease and speed of configuration, which is indispensable for even small batch production and/or processes consisting of many actions.

SELF-LEARNING FOR COMPLETE CUSTOMER AUTONOMY

The customer is completely autonomous in creating and modifying new recipes (processes, product codes) by configuring both visual controls and augmented reality digital instructions.

In fact, the configuration is done in self-learning mode, showing the system the operation to be performed and saving it in the desired sequence.

Hardware installation and calibration are very quick, making the solution to all intents and purposes plug and play and easily re-configurable.

MULTIPLE SENSORS FOR VERY LARGE OR OCCLUDED AREAS

The flexibility of the software also allows the use of multiple sensors with a single control unit to, for example, double/triple the viewing area or perform checks in areas not easily accessible from a single perspective.

A SINGLE SYSTEM REPLACING MULTIPLE OBSOLETE COMPONENTS

SRv3 is an all-in-one, digital, flexible solution and clears the work surface.

It replaces a long series of quality control, operator support and interface devices which are obsolete in comparison with SRv3.

This saves the customer the costs of purchasing hardware components, integration tasks and all the hardware maintenance that multiple systems and their wiring require.

UN UNICO SISTEMA CHE SOSTITUISCE MOLTEPLICI COMPONENTI OBSOLETI

La soluzione SRv3 di Smart Robots è all-in-one, digitale, flessibile e sgombra il piano di lavoro.

Sostituisce una lunga serie di componenti di controllo qualità, supporto operatore e interfacce ormai obsolete al confronto con SRv3.

Il cliente può così risparmiare i costi d’acquisto dei componenti hardware, delle attività di integrazione e di tutte le manutenzioni hardware che i molteplici sistemi e i relativi cablaggi richiedono.

Con sistemi tradizionali

TECHNICAL DATA

Coverage of a working area of up to 9 square metres with a single sensor, which can be extended with several sensors

FAQ

CONTACT US

We are available to provide more information, evaluate your application case, organize a demo of the solution, provide technical support or evaluate commercial partnerships