Smart Robots’ solutions have been successfully applied in a number of very different industries, from automotive and home appliances to electronics, aerospace, and many others.

Indeed, they are used in any location with manual operations whose errors can cause issues to the company.

The most frequent applications are assembly of both small and large parts, packaging and kitting, tightening solutions, and machine tending.

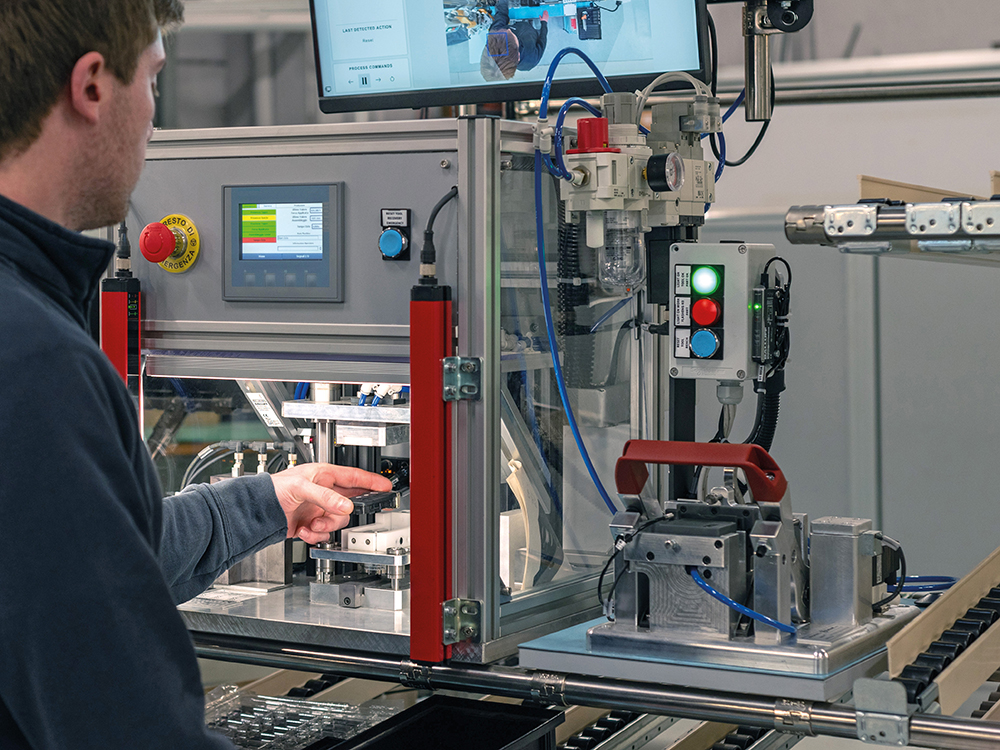

ASSEMBLY

By verifying the picking from the boxes, the presence of components in the assembly, the use of tools and the correct tightening, Smart Robots certifies each step of the assembly sequence for both simple and complex parts, both small and large.

CASE STUDIES

The case studies carried out on our customers’ applications provide first-hand experience of the benefits obtained and how our solutions are used

AVOIDS ERRORS IN BOTH 20-SECOND CYCLES AND 3-HOUR ASSEMBLIES

Humans, also outside factories, make most mistakes in two conditions:

- when they perform very simple, repetitive and routine activities, due to distraction and loss of concentration, or

- when they perform very complex, long and articulated activities that can cause confusion and make people forget some steps.

In production, errors are therefore frequent both in simple, repetitive assembly-line applications and in small batch production with numerous codes and many steps.

VERY SHORT AND REPETITIVE CYCLES

The product has been applied in home appliance and automotive assembly lines with low cycle times and reduced number of actions.

Distraction is very common and can cause high costs.

SRv3 immediately intercepts the error in case of operator distraction so that it can correct itself.

COMPLEX CYCLES WITH MANY ACTIONS

Professional HVAC assemblies, large motors and very complex components are characterized by very long cycles and a large number of different codes.

There is a high risk of the operator missing a step in the assembly, causing high rework costs.

Operator guidance in augmented reality is essential, and the few remaining errors are immediately recognized and resolved.

INTEGRATION IN ANY LAYOUT

The easy installation and configuration of the SRv3 kit allows its easy integration into any pre-existing manual workstation.

LINE IN DISCRETE AND IN CONTINUOUS FLOW

Line advancing step-by-step, or in continuous motion, used for large batch production.

It is common in the home appliance industry and many others.

SRv3, mounted above the line, directly monitors and illuminates the component being assembled on the line, tracking it even as it moves, and simultaneously monitors any static shelf around it.

WORKBENCH

Classic static workstation, widely used in industries for its adaptability.

SRv3 is mounted directly to the workbench, monitoring and guiding the operations on both the bench surface and the shelves.

CELL ASSEMBLY

Stations where the operator assembles a bulky product by moving around it.

It is very common in aerospace, professional HVAC, furnitures, agricultural machinery or automotive, such as for seat assembly.

SRv3 is mounted vertically and sometimes to the side of the product to cover each perspective where critical operations are performed.

CONTACT US

We are available to provide more information, evaluate your application case, organize a demo of the solution, provide technical support or evaluate commercial partnerships